Commonly known as 3D printing, additive manufacturing utilizes a laser beam to fuse successive layers of material on top of one another to build a 3D object. Additive manufacturing lowers prototype tooling costs, reduces inventory, avoids downtime, and cuts waste.

During the solidification phase of the fusion process, reactive gases such as oxygen and carbon dioxide can contaminate the material and negatively affect the quality of the finished product. Therefore, an inert gas such as nitrogen or argon, is used inside the chamber to displace atmospheric contaminants. While the gas pressure and flow needed to keep the atmosphere inert for each process may vary, maintaining a flow rate of 10-20 LPM and a pressure of 15-30 PSIG (1-2 BAR) is recommended. For withdrawal from high pressure cylinders, the CONCOA 619 Series pressure differential switchover with integral purge, combined with the 56H Series regulator, delivers a continuous gas supply without compromising purity. Combining a 629 Series MicroManifold permits an unlimited number of manifold stations connected to a single header, thereby streamlining the handling of gas cylinders.

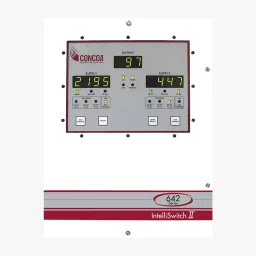

The 632 Series pressure differential switchover provides a continuous supply of shielding gas from high pressure cylinder sources. For optimal performance from liquid cylinder supplies, CONCOA recommends the 640 Series IntelliSwitch or the 642 Series web-enabled IntelliSwitch II, which provides continuous gas pressure and flow control safely and efficiently from two banks of cryogenic liquid cylinders. CONCOA IntelliSwitch systems are designed with electronic look-back and economizer features for optimal primary and secondary cylinder utilization. Additional features of the 642 IntelliSwitch II include proprietary onboard connectivity, which allows remote monitoring, secure system configuration, and real-time email notifications and updates. IntelliSwitch systems are scalable. Should nitrogen demand increase, gas cylinders can be added. Should demand decrease based on seasonal or variable production, cylinders can be removed. CONCOA IntelliSwitch systems interface with Altos 2 remote alarms, which signal audible and visible warnings of cylinder depletion.

With repetitive chamber cycles, unsafe oxygen levels may result. CONCOA gas sensors and monitors, such as the 580 Series oxygen deficiency monitor, ensure continuous detection and measurement of ambient oxygen levels. The monitor may be used as a stand-alone gas detector, with the 585 Series emergency shut-off controller or emergency stop button, or connected to a centralized gas monitoring system to ensure a safe breathing environment. As additive manufacturing technologies emerge, CONCOA provides pressure control and safety equipment for the desired level of manufacturing capacity.

Additive manufacturing has evolved to the point where it is now possible to “print” with metal. Industrial additive manufacturing, commonly referred to as industrial 3D printing, requires the use of inert gases at every step throughout the process. Improve your process with reliable solutions from CONCOA, including process equipment for gas mixing and flow control, innovative gas distribution systems to supply gas to your process, gas analyzers to ensure the right atmosphere for your 3D printing chamber, and CONCOA alarms and gas detection devices to increase safety and minimize risk.