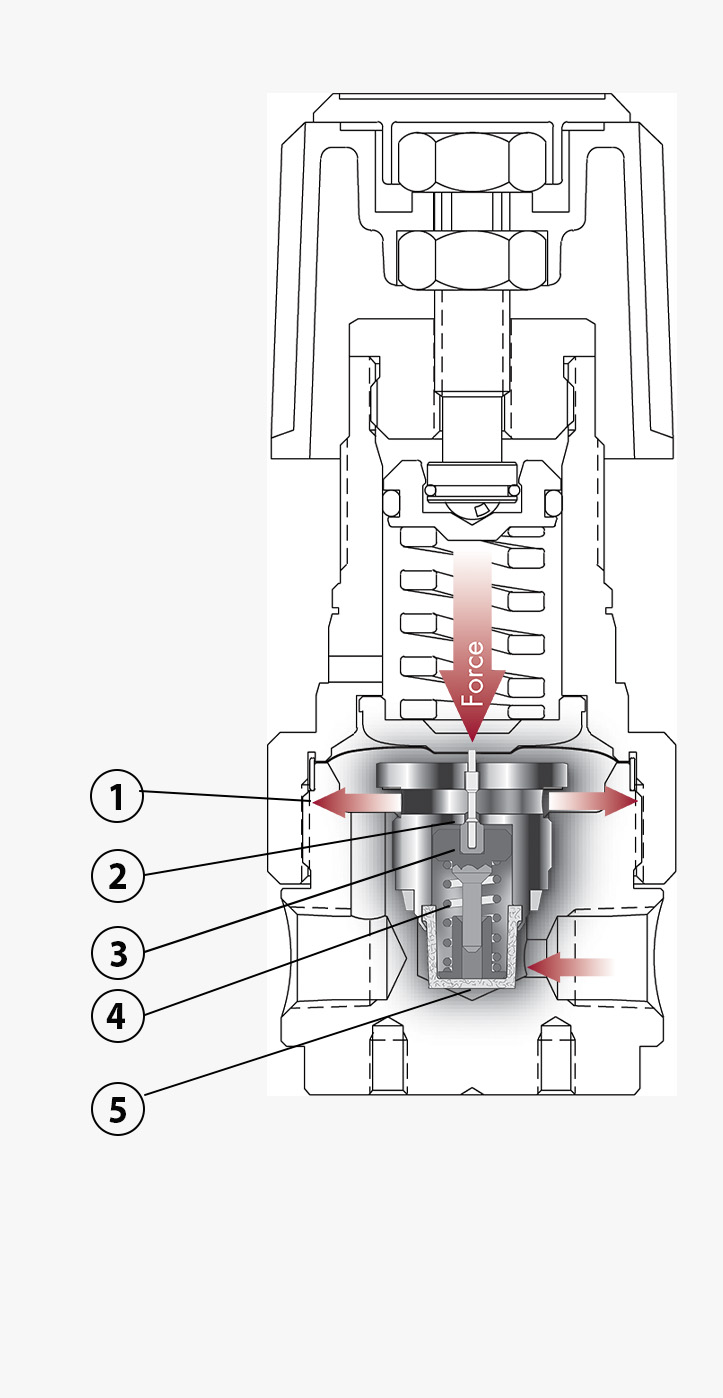

To meet the rigorous requirements of end users in the analytical, scientific, and electronics markets, CONCOA has developed a unique regulator seat assembly that incorporates the numerous individual parts of a standard regulator seat into a single component. This design allows the CAPSULE® to be tested as a separate component prior to assembly into the regulator. The completed regulator is also 100% tested, giving the seat, or "heart" of the device, a double test. The result is longer life and reliable performance.

1. Lateral Flow Passages

Instead of impinging directly on the diaphragm, the gas enters the low pressure chamber through a side orifice of the CAPSULE. This smooth transition from high pressure to low pressure reduces the effects of gas surge on the diaphragm and minimizes regulator hum. In addition, the lateral flow passages induce a swirling effect which yields a completely swept internal cavity for complete purging.

2. Multiple Orifice Sizes

Each regulator has a specially designed CAPSULE to optimize regulator characteristics over a broad range of applications. However, there are applications requiring higher or lower flows than the standard CAPSULE can offer. By substituting a CAPSULE with a larger or smaller orifice, CONCOA can tailor the regulator to meet a specific requirement.

3. PTFE or PCTFE Seat

The standard seat material is high density PTFE. PTFE is an inert material which will not react with or contaminate any high purity gas. In addition, PTFE retains its sealing properties over a wider temperature range than other seat materials. Though it shares properties of PTFE, PCTFE is a harder material that affords a higher maximum inlet pressure. CONCOA recommends a PCTFE seat for initial pressure regulators at a high pressure source, and PTFE for final line regulation of initial pressure regulators from lower pressure sources.

4. High Load Marginal Spring

The purpose of the marginal spring is to close the seat independently of gas pressures. The innovative CONCOA CAPSULE utilizes a high force spring that assures a gas-tight seal under all conditions.

5. 10-Micron Filter

Particles trapped between the seat and orifice prevent proper seat closure, causing the regulator to fail. The CAPSULE incorporates a 10-micron filter which completely surrounds the seat components to prevent the entrance of these damaging particles, virtually eliminating the cause of such seat failures. In addition, this filter is very fine, and its large surface area is resistant to clogging, which allows unrestricted flow. The 10-micron filter is a key factor in the long life and reliable performance of all CONCOA regulators. The stainless steel 10-micron mesh CAPSULE is patented CONCOA technology.