While all regulators can reduce pressure in a gas system, CONCOA high purity regulators conform to very exacting standards of pressure control. Below, we discuss some basis of comparison that can help you navigate this catalog and choose a regulator that best suits your needs. Of course, our Customer Service representatives would be happy to answer any further questions you may have about regulator design and operation.

Single Stage vs. Dual Stage

Single stage regulators reduce pressure in a single step to deliver a pressure within a specific range. Regulators designed in this way will show a slight variation in delivery pressure as the cylinder pressure falls during use. For this reason, single stage regulators are best suited for applications where a constant outlet pressure is not critical, where an operator can monitor and readjust pressure, or where inlet pressure is constant. Dual stage regulators perform the same function of reducing cylinder pressure to a usable level but do so in two steps. This two-stage process ensures delivery pressure remains constant as cylinder pressure decreases, providing greater accuracy in pressure control. Dual stage regulators are recommended for applications requiring a constant outlet pressure over the life of a gas cylinder.

Helium Leak Integrity

Helium Leak integrity is a measurement of how well a regulator prevents gases from leaking into or out of a regulator body. The measured quantity is expressed as a flow rate such as 1 x 10-9 scc/sec He (1 billionth of a cc/sec). In this case, a Helium Leak integrity rating of 1 x 10-9 would indicate that the regulator would leak enough gas to fill one cubic centimeter every 33 years. If the rating were 1 x 10‑3, the regulator would leak enough gas to fill one cubic centimeter in just 17 minutes. Helium is used as the test gas because it is chemically inert, it is easy to detect, and it is an extremely small molecule with the ability to pass through the smallest leak. The lower the Helium Leak specification, the better the regulator will be at preventing leaks into the atmosphere and at minimizing contamination from gases outside the body. This is particularly important in sensitive analytical applications where even trace amounts of impurities can compromise results.

Materials of Construction

The materials of construction for a regulator should be selected based on the properties and purity of the gas being used. CONCOA manufactures regulators from brass, 316L stainless steel, and chrome-plated brass. Brass is compatible with most of the non-reactive gases. It is economical and provides reliable performance in standard applications. A choice of forged body or barstock construction is available. Forged body regulators are economical; however, their internal surface finishes are relatively rough as compared to barstock body regulators. Barstock body regulators have all wetted surfaces machined to a smooth finish, which reduces the possibility of contamination. Because of its exceptional corrosion resistance, 316L stainless steel is ideal for many of the highly corrosive gases in their anhydrous form. Its strength and durability ensure longevity in demanding environments. Chrome-plating brass regulators combines the advantages of brass with an additional layer of protection. The chrome plating provides a smooth, hard surface that enhances wear resistance and reduces the potential for contamination. This makes them suitable for applications requiring a higher level of cleanliness and aesthetic appeal. Refer to the compatibility charts or consult your gas supplier to determine suitable materials of construction.

Specialized Treatments

In applications where 316L stainless steel is not sufficiently inert or corrosive resistant, CONCOA offers regulators with specialized treatments to ensure superior analytical accuracy and durability. For instance, CONCOA's 420 Series, 430 Series, and the 515 Series are treated with SilcoNert™ 2000. This proprietary amorphous silicon coating significantly enhances corrosion resistance and inertness, making them ideal for handling reactive calibration standards. Additionally, the 455 Series regulators feature electroless nickel-plated bodies with Dursan® treated internal components, providing excellent resistance to highly corrosive gases such as chlorides and sulfides. For applications involving fluorine, CONCOA offers passivation treatments to further enhance compatibility and performance.

Cylinder Connections

CONCOA manufactures cylinder connections that comply with worldwide standards. In the US, the Compressed Gas Association (CGA) has designated specific cylinder connections for each gas service and pressure rating. There is approximately a dozen commonly used CGA fittings, with others used for specialty purposes. To identify the correct CGA fitting for a specific gas, refer to the CGA Fitting Reference Chart, which provides standard inlet connections, corresponding gas types, and other relevant information. It is important to note that a CGA connection limits the temperature range of a regulator to the specifications of that connection. Beyond CGA standards, CONCOA also offers cylinder connections that conform to international standards, including DIN 477, BS 341, JIS (Japan), and AS (Australia).

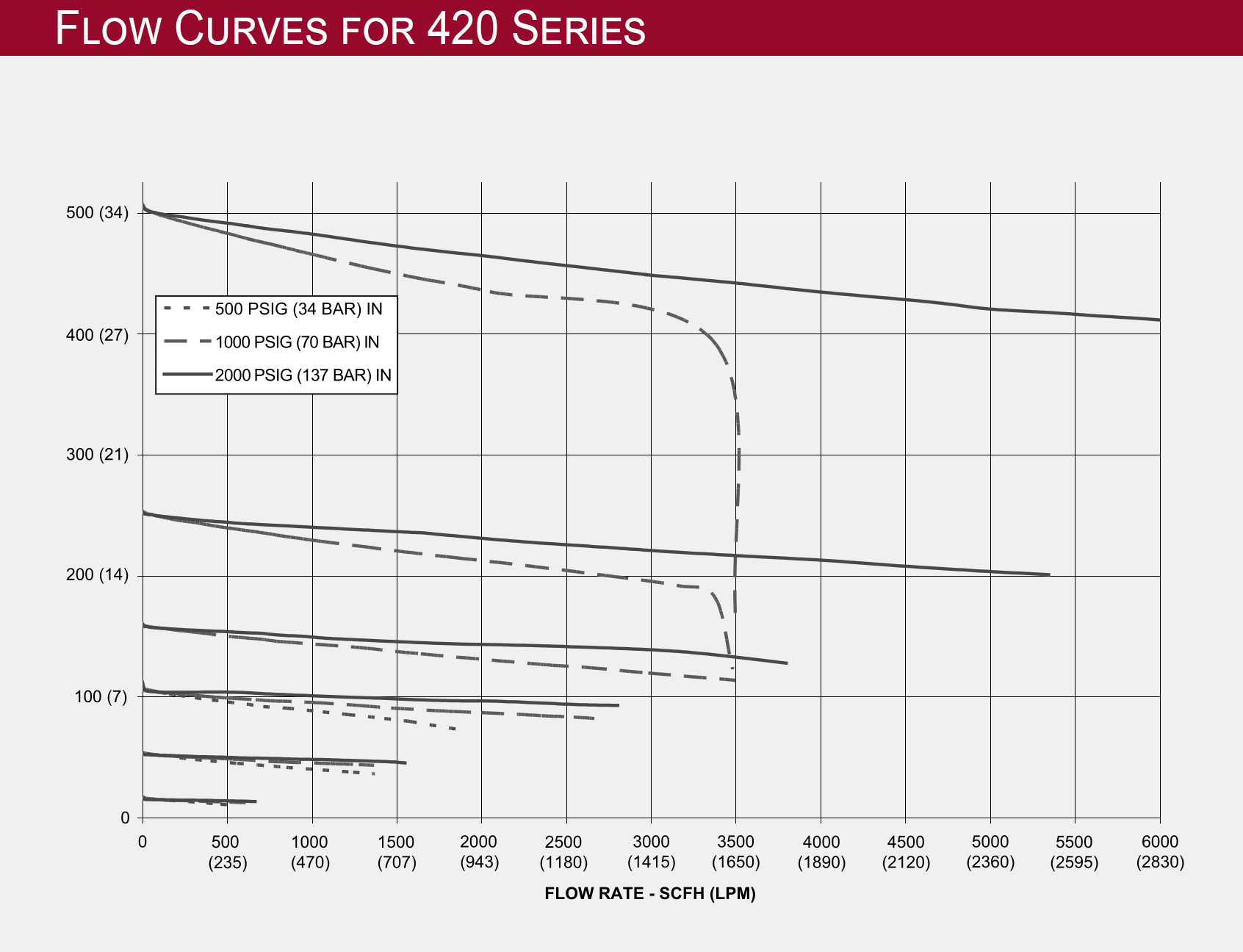

Flow Charts

Flow charts are a graphical representation of test results which show how outlet pressure varies with flow rate under specific conditions. To use the chart, determine the maximum no-flow pressure permitted by your system. Locate this pressure on the vertical axis of the chart. If there is no curve for your specific condition, interpolate a curve. Follow the curve to the desired flow rate on the horizontal scale. Read horizontally to the left to determine the corresponding pressure drop. Because flow rate is dependent upon inlet pressure, data is presented for a full cylinder at 2000 PSIG (137 BAR), partially full at 500 PSIG (34 BAR), and nearly empty at 200 PSIG (14 BAR). The goal is to choose a regulator with a relatively flat curve within your operating range. If your conditions fall in areas with steep drops, a different model might be better. By carefully analyzing flow curves, you can ensure that the chosen regulator will perform reliably within your system's specific parameters.

Diaphragms

The diaphragm is a sensing element crucial to the function of the regulator and the purity of gas delivery. Stainless steel diaphragms are corrosion-resistant and have low leakage rate characteristics. They are preferable in applications involving high pressures, elevated temperatures, or highly corrosive environments where enhanced durability and corrosion resistance are critical. Chloroprene diaphragms are more flexible than stainless steel, allowing for more sensitive pressure control. However, they do not offer the gas purity of stainless steel. Therefore, while chloroprene diaphragms may be suitable for some standard industrial applications where ultra-high purity is not a critical requirement, stainless steel diaphragms are generally preferred in scenarios demanding stringent gas purity and enhanced durability.

If you are unsure about your specific requirements or need assistance selecting the appropriate regulator for your application, please contact CONCOA's customer service team.