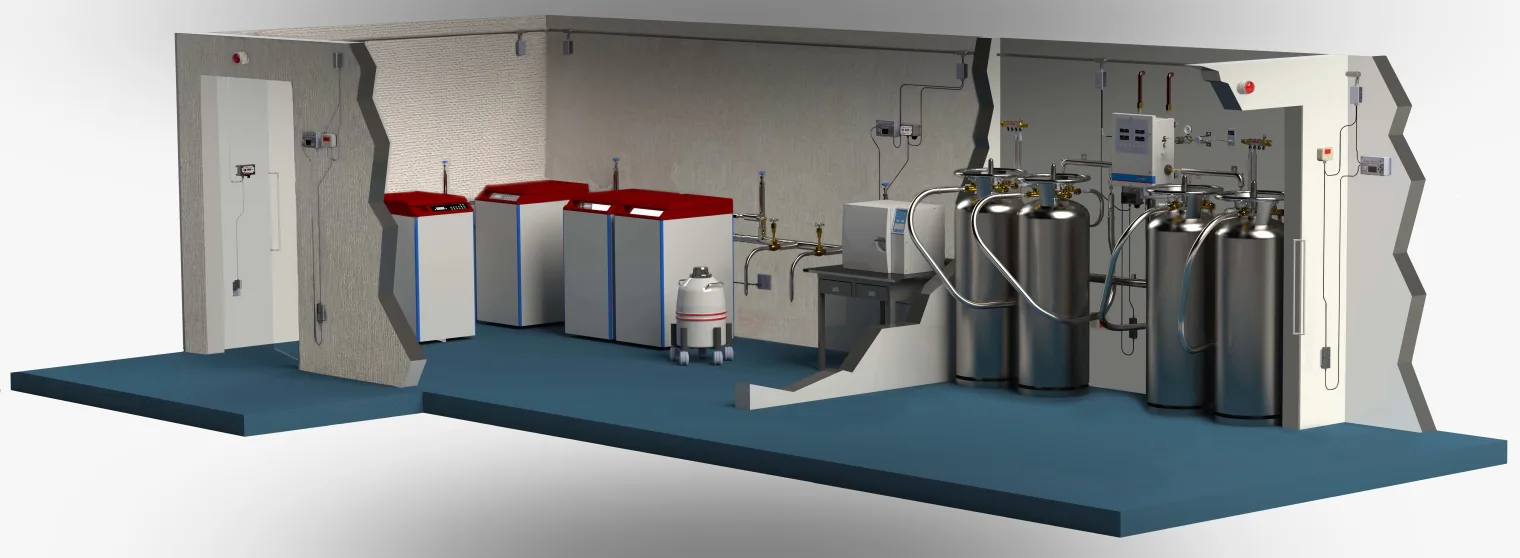

CRYOGENIC SOLUTIONS FOR LIQUID NITROGEN IN LABORATORY APPLICATIONS

Advanced System Technology

Designing a liquid nitrogen (LN2) supply system is highly complex due to extreme temperatures, phase changes, and the necessity to minimize heat transfer. Proper insulation, temperature regulation, and flow control are essential to prevent excessive boil-off and LN2 loss. CONCOA is the only manufacturer to offer a true single-source solution. From the vacuum-jacketed (VJ) piping and advanced CryoWiz™ Switchover to system integration, controls, and monitoring, CONCOA designs, manufactures, and supports the entire package, delivering a reliable, end-to-end solution tailored to the specific demands of cryogenic laboratory applications.

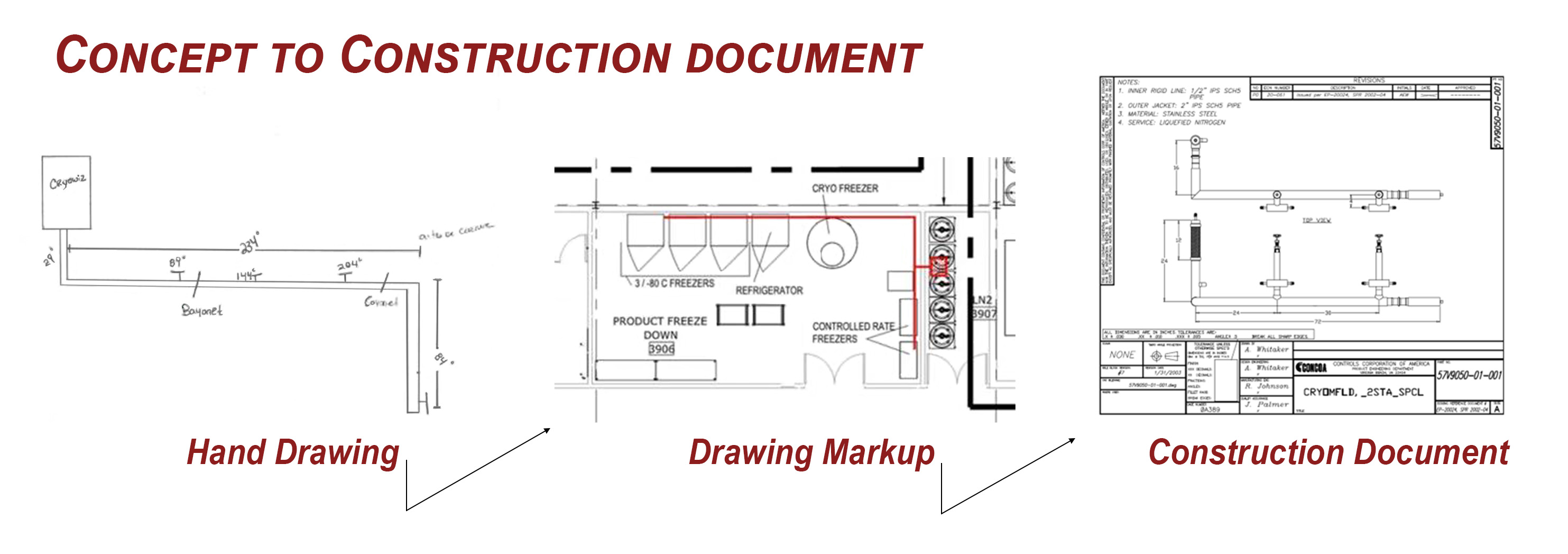

Customized Piping Layout

CONCOA’s approach for custom-tailored VJ piping begins with a comprehensive evaluation of site drawings or an on-site visit to confirm measurements, identify physical or structural constraints, and determine system requirements. In-house engineers then design the most efficient pipe routing, minimizing unnecessary lengths from source to point-of-use to reduce heat loss. The completed VJ piping system, fabricated to exact specifications, is shipped in pre-assembled sections and ready for installation, simplifying the process for local contractors.

a comprehensive evaluation of site drawings or an on-site visit to confirm measurements, identify physical or structural constraints, and determine system requirements. In-house engineers then design the most efficient pipe routing, minimizing unnecessary lengths from source to point-of-use to reduce heat loss. The completed VJ piping system, fabricated to exact specifications, is shipped in pre-assembled sections and ready for installation, simplifying the process for local contractors.

Superior Thermal Performance

Every component of CONCOA’s custom-engineered cryogenic pipeline, from main distribution lines to critical points like isolation valves and end-use connections, is manufactured to prevent heat ingress. CONCOA’s VJ piping features super-insulated technology that minimizes the effects of conduction, convection, and radiation. Additionally, getter materials inside the annular space maintain the long-term integrity of the insulating material and the vacuum seal for superior thermal performance. These components work as a cohesive system, ensuring compatibility throughout the installation and enabling scalability as demand increases.

Optimal Supply Management

The CryoWiz Cryogenic Switchover is the centerpiece of CONCOA’s total system solution. Utilizing proprietary software, it automatically transitions between primary and reserve sources to ensure an uninterrupted cryogen supply. Equipped with pneumatically controlled valves to minimize heat transfer, the CryoWiz facilitates intelligent flow control via two modes of operation: On-demand and Keep-full. This coordinated functionality lies at the core of the CryoWiz system's ability to deliver precise and efficient cryogenic fluid management tailored to real-time application demands.

Heat Transfer Rates by Hose/Pipe Type

Regardless of design, all cryogenic pipes and hoses have some degree of heat transfer. While the heat transfer rate may not always be clearly stated in product specifications, it is always present and directly impacts a system’s performance and efficiency. Understanding heat leak in cryogenic hoses and pipes helps predict cryogen boil-off, manage pressure rise, and optimize overall system performance. The table below summarizes the comparison of heat transfer rates and total heat load of various cryogenic transfer lines to show how CONCOA's VJ piping outperforms traditional options in reducing heat loss.

| HEAT TRANSFER PROFILES OF VJ HOSES AND PIPES | ||

|---|---|---|

| Hose/Pipe Type | Heat Transfer Rate (BTU/hr/ft) | Total Heat Load (BTU/hr @20 ft) |

| Traditional Foam-Insulated Pipe | 20.00 – 30.00 | 400 - 600 |

| Traditional Flexible Vacuum-Jacketed Pipe | 2.00 – 4.00 | 40 – 80 |

| Traditional Rigid Vacuum-Jacketed Pipe | 2.00 – 3.00 | 40 – 60 |

| CONCOA's Ultra-Flexible Vacuum-Jacketed Piping (551 2200 Series) | 0.74 – 2.14 | 15 – 43 |

| CONCOA's Semi-Flexible Vacuum-Jacketed Piping (551 2000 Series) | 0.32 – 0.70 | 6 – 14 |

| CONCOA's Rigid Vacuum-Jacketed Piping | 0.42 | 8 |

Engineered to deliver significantly lower heat transfer rates, CONCOA’s VJ pipes and hoses improve thermal efficiency, reduce LN2 consumption, and ensure safe, fail-proof operation, making it the best-in-class solution for LN2 delivery. Call CONCOA for a total package solution tailored to meet the specific needs of your cryogenic laboratory applications.