Plasma cutting uses an accelerated jet of ionized gas to cut through electrically conductive materials. Plasma cutters are utilized in light and heavy industries wherever quick, accurate, and precise cutting of flat metals, including stainless steel, copper, aluminum, titanium, steel, iron, and alloys, is required.

Plasma torches and plasma cutters heat compressed air or gas to over 36,032 ⁰F (20,000 ⁰C) to create an ionized, superheated plasma beam. The plasma beam melts any electrically conductive material it touches to make a clean, sealed cut. The type of gas used in plasma cutting depends on the cutting method, material, and thickness. Plasma cutters need an air or gas supply of approximately 100 PSIG (9 BAR). The CONCOA 6800 Series heavy-duty regulator provides high flow rates and pressure control of up to 250 PSIG (17 BAR) for gases commonly used in plasma cutting, such as air, nitrogen, argon, and hydrogen. For pressure control at the source, the 605 Series high flow manifold regulator designed with a flat, balanced seat allows the user to adjust the pressure as needed. For gas pipeline systems, the CONCOA 6790 Series high flow, heavy-duty regulator, with 1/2 inch ports, provides the best point-of-use performance.

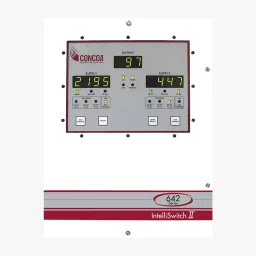

For continuous gas supply or higher duty cycles, the CONCOA 632 Series pressure differential switchover with remote alarm option is a cost-effective solution, providing high-flow capacity from two separate banks of cylinders feeding a shared 6700 Series manifold regulator. For fully automatic switchover from multiple cylinders, CONCOA recommends the 642 Series IntelliSwitch II™ with electronic look-back and economizer features for optimal primary and secondary cylinder utilization. In addition, the CONCOA 642 Series IntelliSwitch II system, featuring proprietary onboard connectivity, allows remote monitoring, secure system configuration, and real-time email notification and updates. Finally, CONCOA recommends integrating the Altos 2 remote alarm for complete flow monitoring and system maintenance.

CONCOA's plasma cutting regulators are designed to deliver precise pressure control instantaneously. The innovative 67B Series high flow, high-pressure regulator achieves these results with its flat seat and balanced stem seat design. Available in either 1/2-inch or 3/4-inch port sizes makes it the ideal choice for plasma cutting applications.